Extension springs in 4280 spring sizes for fast delivery from stock made of normal steel EN 10270-1 and stainless steel 1.4310 from Gutekunst. The extension springs are made of round spring steel wire in a cylindrical shape with a 1/1 German eyelet on each side and a linear spring characteristic in quality grade 2 (medium tolerance range) according to DIN EN 15800. Simply select the right tension spring in the spring shop and order it directly from Gutekunst via the shopping cart. CAD data, data sheets and spring characteristic diagrams are available for each extension spring.

Extension springs catalog range

Extension springs in 2348 dimensions made of normal steel EN 10270-1 (not rustproof, max. Temperature 80 degrees) in wire thicknesses (d) from 0.2 to 8.0 mm from stock.

Extension springs in 1932 dimensions made of stainless steel 1.4310 (rustproof, max. Temperature 200 degrees) in wire thicknesses (d) from 0.2 to 4.0 mm from stock.

Extension springs made of normal steel are lightly oiled after the thermal treatment. Stainless steel extension springs are not treated any further after the thermal treatment. Additional surface treatments of the extension springs have the disadvantage that the application of the surface is only possible with great effort due to the pretensioning of the spring body. Here, the choice of a suitable spring material is preferable to subsequent surface treatment. In this case, contact order@gutekunst-co.com .

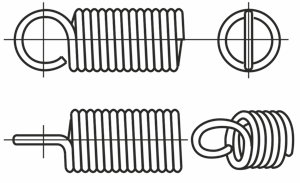

Winding direction, loop shape and loop position

Our extension springs are right-wound as standard (clockwise). A 1/1 German eyelet according to DIN 2097 is bent at both ends of the spring body. The eyelets have no opening in stock (m = 0). However, we can cut open an eyelet opening at short notice if necessary.

1/1 German loop

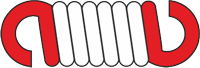

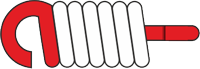

Each extension spring is available from stock with 2 different loop positions. One loop position is 180 degrees (article numbers with the letter "I"). The other position is 270 Graf (article numbers with the letter "X").

Loop position 180 degrees ("I")

Loop position 270 degrees ("X")

Spring test

All metal springs are quality checked. This is done in our testing department, which is independent of production. The testing of the tension springs offered in the catalog range is carried out in accordance with DIN ISO 2859-1 test level II. The procedure is based on the single sample plan for normal tests with test severity AQL = 1.0. If necessary, we can carry out and document all test regulations up to and including individual tests. We offer the following factory certificates for each test item.

Factory certificate according to:

EN 10204-2.1 (DIN 50049-2.1) free of charge

EN 10204-2.2 (DIN 50049-2.2) subject to charge *

EN 10204-3.1B (DIN 50049-3.1B) subject to charge *

*Price on request

Calculation, tolerances and production compensation

The calculation of the tension springs was carried out according to EN 13906 Part 2. The specified tolerances for the tension spring correspond to quality level 2 from DIN EN 15800. In order to be able to adhere to the tolerated dimensions, a production compensation is made via the preload (F0) or the mean coil diameter (D).

Use of the extension spring

The extension springs can be used with the specified distances and forces for static or seldom loads. In all other cases, a mathematical check of the application should be carried out. Since the attachment point of the eyelet is the critical point for possible breaks in extension springs, the stresses occurring there must be checked. Often it can be done by choosing another loop shape a longer service life can be achieved.

More information about Types of stress

Shipping and prices

The spring shop order is ready for dispatch within 2 - 5 days (*). The dispatch takes place in Germany with DHL, in Europe with DHL or DPD. Outside Europe, we only ship with the customer's shipping account.

The item prices are displayed in different quantity scales up to an order quantity of 550 pieces. For larger order quantities, you can see the currently valid item price in the order confirmation. Price information for larger order quantities by phone (+49) 07123 960-192 and order@gutekunst-co.com.

Gutekunst does not charge surcharges for small quantities for small orders!

(*) It usually takes 2 - 5 days to prepare for dispatch. If the item is not in stock, it can take up to 28 days to prepare for shipment.

Gutekunst Federn